-

CERAMIC COATINGCALL THE SPECIALISTS

CERAMIC COATINGCALL THE SPECIALISTS -

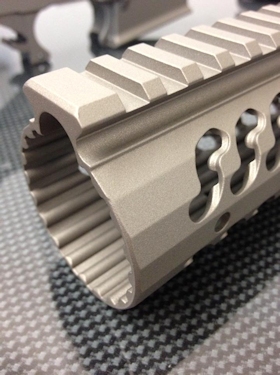

SUPERIOR RESULTSHEAT AND CORROSION RESISTANT

SUPERIOR RESULTSHEAT AND CORROSION RESISTANT

-

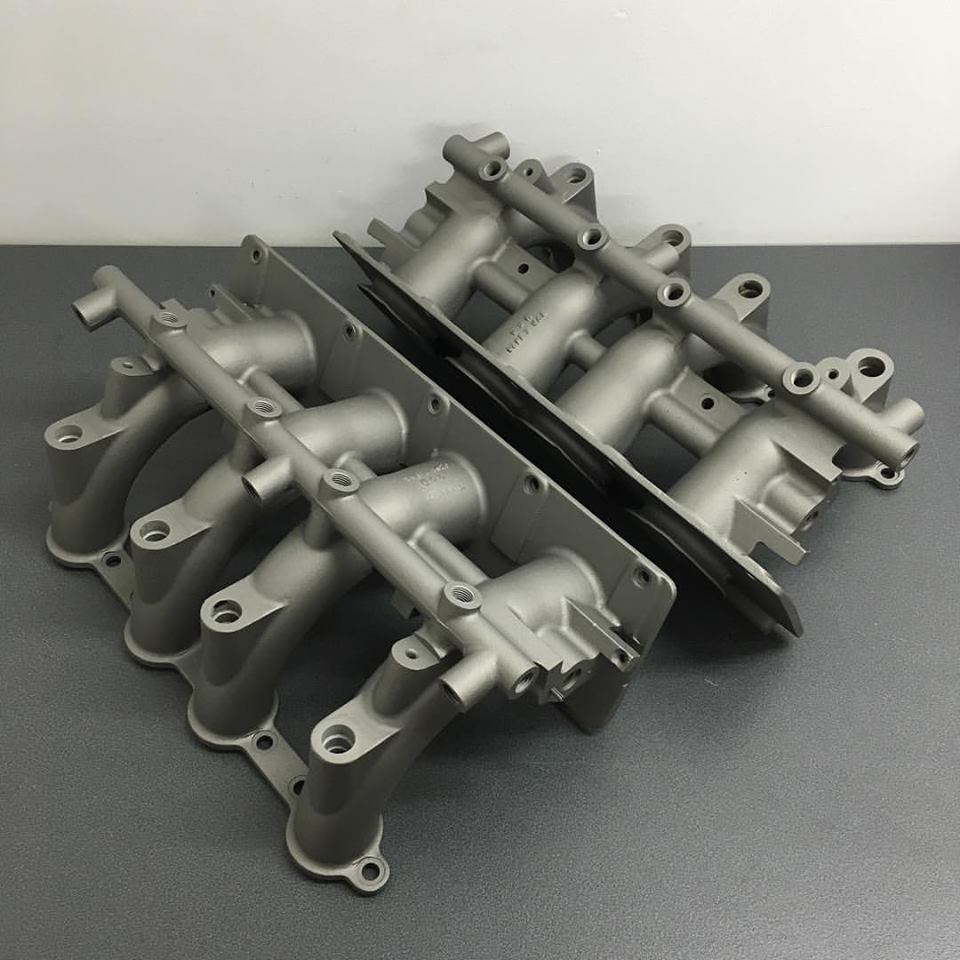

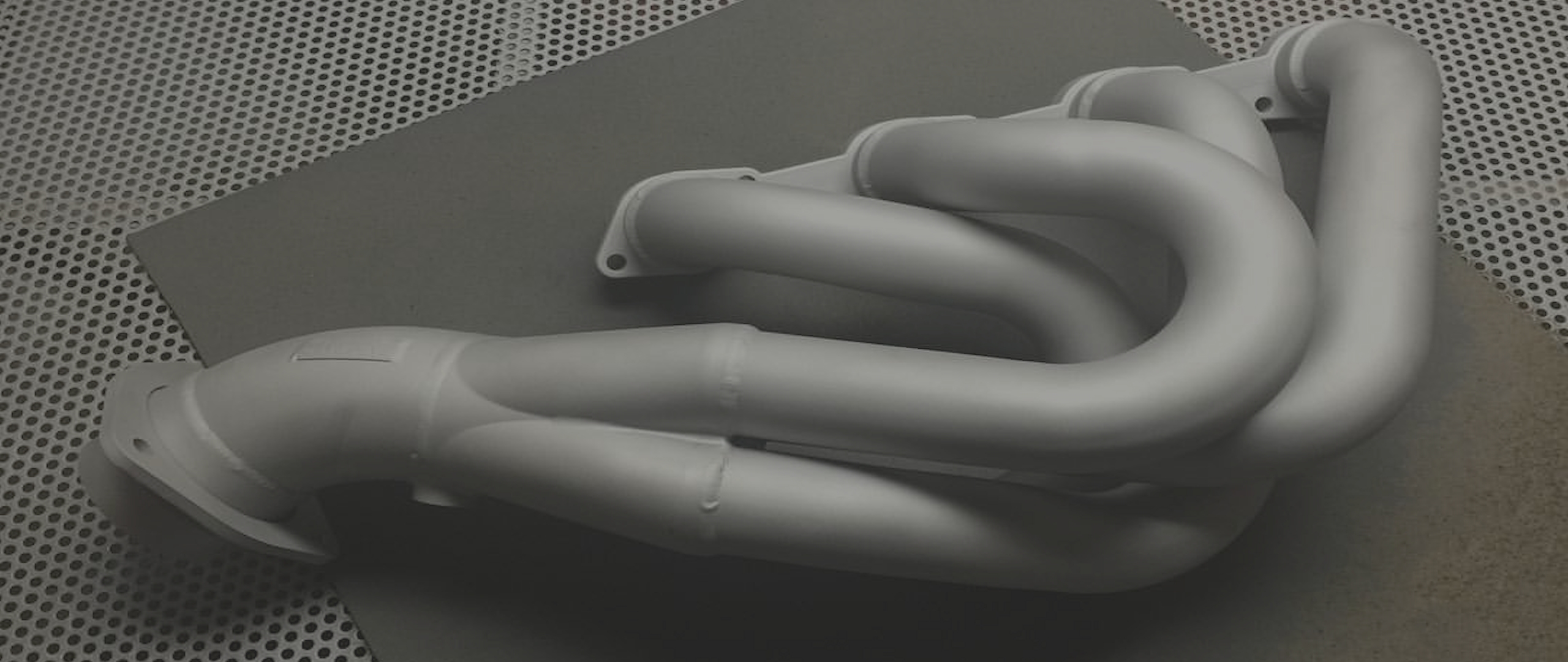

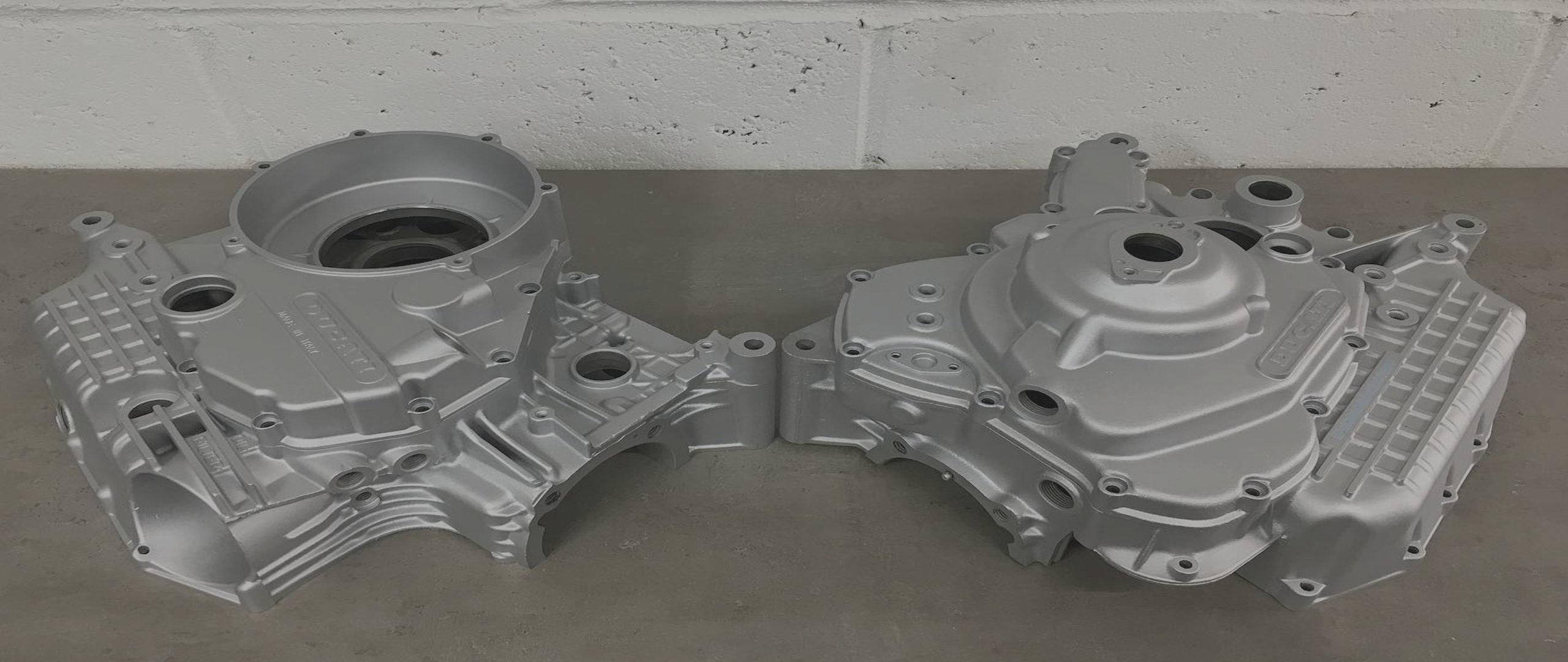

DURABLE & TOUGHCERAKOTE® 'CUSTOM MAGNESIUM' FINISH

DURABLE & TOUGHCERAKOTE® 'CUSTOM MAGNESIUM' FINISH -

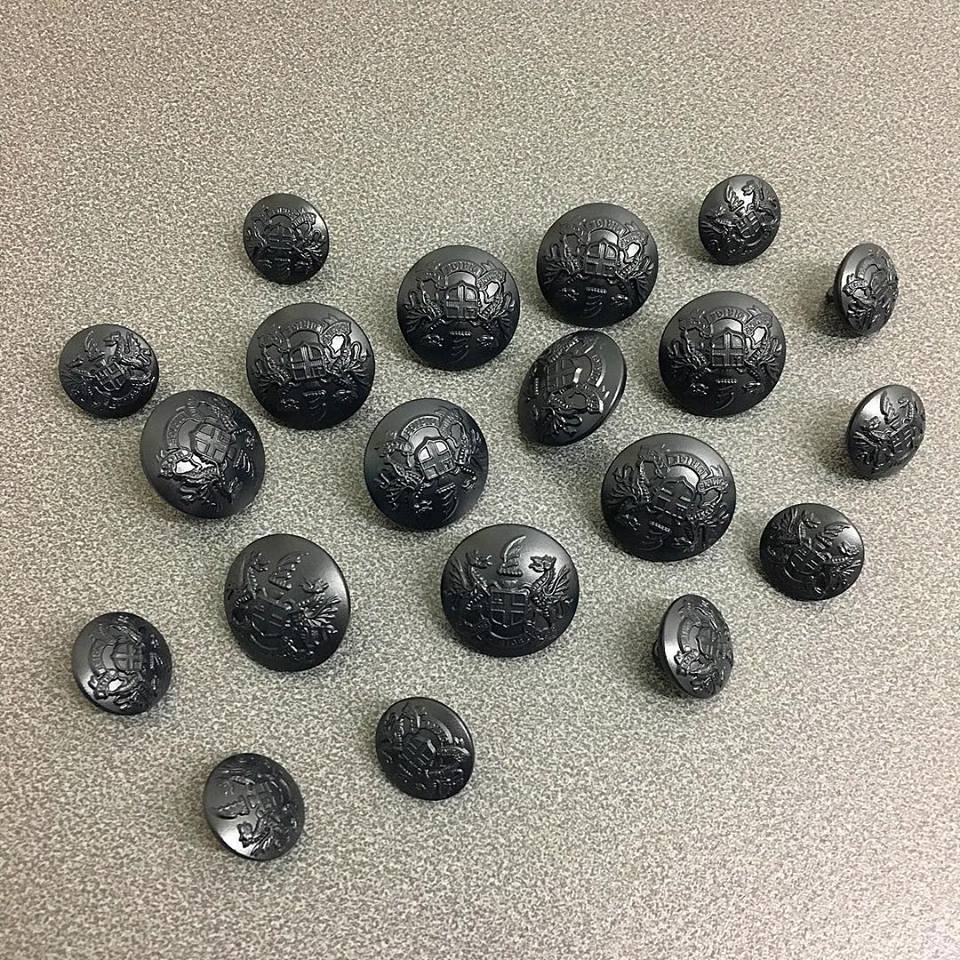

MANY APPLICATIONSCERAKOTE® 'GLACIER SILVER' FINISH

MANY APPLICATIONSCERAKOTE® 'GLACIER SILVER' FINISH -

-->

VAPOUR BLASTINGWE OFFER AN IN-HOUSE SERVICE

-->

VAPOUR BLASTINGWE OFFER AN IN-HOUSE SERVICE

About Us

Hi-Spec Coatings, based in Slinford, West Sussex, has established itself within the industry as one of the top specialist coating companies in the UK. Founded in 2013 by Wesley Dunford, we have become highly sought after for the quality of our work and professionalism. The company exhibits at a number of trade shows and events throughout the year, as well as running a busy workshop, having recently moved to new premises.

We are an approved centre for Cerakote®, a unique product that is comprised of a ceramic based coating with an incredibly durable finish. Hi-Spec Coatings were the first 'Non-Firearms Based' certified applicator in the UK, specialising in automotive application, beginning in 2013. We can apply the coating of your choice, in an array of different colours & there are a number of different formulae available, based on the application involved, such as exhaust manifolds for example. We can advise you as to the best one to use, based on the parts you require coated.

We also offer a number of other services, besides ceramic coating, such as media and vapour blasting. Whatever your needs, we feel confident we can provide you with the solution you are looking for. No job is too big or small, so don't be afraid to ask. For more information, please contact us and feel free to have a look through our gallery, where you will find some examples of our work.

The 'Factory Trained & Certified' logo remains the copyright of Cerakote® and is a mark of quality assurance and compliance. It can only be displayed by an appointed and approved applicator, such as ourselves. We are very experienced with their range of products and are firm believers in their performance, so below is a brief explanation of how and why they work.

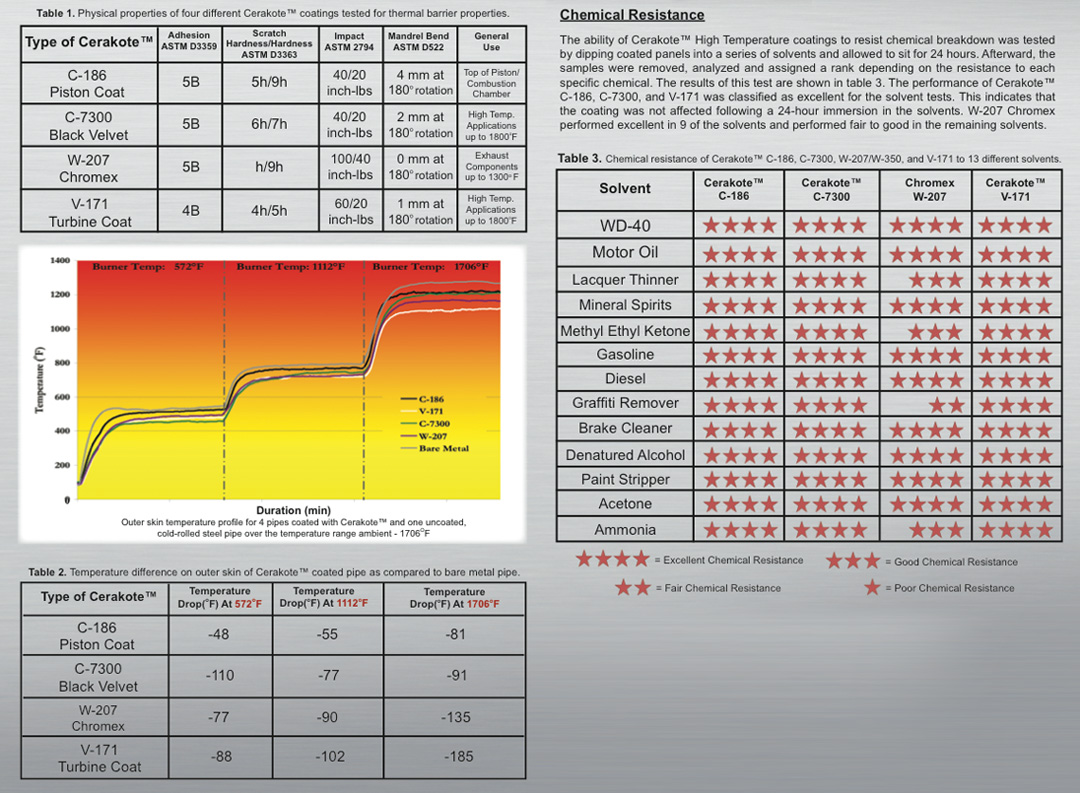

Unlike other 'ceramic' coatings, Cerakote® is formulated at a molecular level. All Cerakote® products begin with a liquid resin, and during the cure process, the resin forms a 3-D ceramic matrix. Additional property-enhancing materials are combined with the raw resin and trapped within the matrix.

The resulting unique, ceramic-based formulation provides a number of physical characteristics, allowing it to function as a thermal barrier for thermally-sensitive applications and creates a durable, heat resistant coating making Cerakote® the premier product available on the market today.

Cerakote® Technical Information

Cerakote® offers four different types of high-temperature products. An outline of each of these coatings is shown below. Cerakote® exhaust coatings are available in both ambient-cure and oven cure systems. Each of the coatings may be used over a number of different substrates, including steel and aluminium. The MC-Series line of ceramic clear coatings is the world's strongest clear coat and is typically used as a protective clear coat over aluminium, steel, brass, PVD, and numerous other paint and powder coatings, to improve their appearance and durability. The average coating thickness ranges from 0.5-1.0 mil and can be used in areas of low tolerance.

Our Services

We offer a range of services at Hi-Spec Coatings. Set out below are just a few examples of what we can offer. If you require a quote, we would always recommend that you discuss your needs with us beforehand so that we can provide you with an idea of the costs involved.

CERAMIC COATING

Ceramic coating is by far and away our most popular service. As one of a handful of appointed companies, we are an approved applicator of Cerakote® and carry an extensive range of colours and assortment of specialized heat resistant products within the range. Used predominently on firearms, the product quickly established itself as the go-to option, when it came to high-temperature applications, such as exhaust manifolds and engine casings. That said we are seeing an increasing demand for other uses, such as motorcycle frames, swingarms, wheels, hubs, garden furniture and even watch cases. In fact there is little we cannot coat. For a quote, please contact us to discuss your requirements.

VAPOUR & MEDIA BLASTING

Vapour or media blasting is an essential part of the process in preparing components for paint or to be ceramic coated, though it is equally of use in just cleaning away years of muck, grime and corrosion. The type of blasting we use depends, amongst other things, on the intended use of the product and the finish required. Vapour blasting is especially useful on intricate parts such as engine casings, carburettors and throttle bodies, where conventional media blasting runs the risk of leaving particles inside a vital oil gallery or orifice. Media blasting is effective at dealing with tougher jobs, such as the rapid removal of surface corrosion and rust from metal parts, such as wheels or motorcycle frames. We can advise you as to the best option to use.

Expression of Excellence

We take great pride in our work and this is often reflected in the feedback we get from customers, as can be seen from a selection of testimonials we have included on our website. It's not all about the accolades however, as we are driven by the desire to improve our service year on year and have done so, since we first started trading. Investment in new equipment and the recent move to our new facilities in Sussex, has given us the means to take on more work but at a controlled pace, ensuring quality is never compromised.

Gallery

Video: Turn Up The Heat

At Hi-Spec Coatings, we never cease to be amazed at the incredible performance of Cerakote® products. One such example is C-7600 or 'Glacier Black' which is formulated to withstand temperatures up to 1,800° Fahrenheit & thermal shock from those temperatures, directly into water with no adverse effects. C-7600 retains its deep black, sleek satin finish in the most extreme environments. Cerakote® Glacier Series coatings are a line of air cured, ready-to-spray ceramic coatings. If you're still in doubt as to how good this product really is, then just watch this video.